-

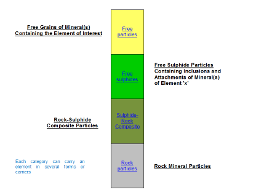

ELEMENT DEPORTMENT

Element deportments are versatile studies that can be used for diagnostic and predictive process mineralogy. The mineralogy of an ore affects all of its chemical processes and consequently, the response of an ore to a metallurgical process can be foretold, if the mineralogy is known. By identifying and quantifying mineral forms and carriers, element deportments provide our clients with a complete breakdown of mineral constituents of an element, in an ore. AMTEL has been a world-wide leader in element deportments for over 20 years.

”An assay can tell you how much of something there is, Element deportments can tell you where, how and how much.”

Elemental deportments can:

- Identify and quantify elemental forms and mineral carriers

- Identify and quantify issues from different perspectives

- Suggest follow up metallurgical test-work for Process Selection and Optimization

- Comprehensive Full Plant Surveys

- Comparative Studies

- Accurate current and potential metallurgical index

-

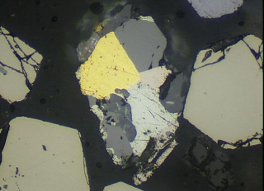

ORE CHARACTERIZATION

Ore and gangue mineralogy has a profound impact on the outcome of a project. The mining methods, extraction process requirements and in particular, performance of all chemical processes involved in extraction are affected by the mineralogy.

With ore grades decreasing and the complexity of mined reserves increasing, mineralogical data and characterization is required.

AMTEL’s Ore Characterization provides our clients with the proper insights for understanding issues and potentials early in the development stages.

- Complete ore and gangue mineral characterization and quantification

- Liberation analysis

- Impacts on processing and storage (Milling, Floating, Leaching, Tailing Storage, ect.)

- Identify and assess deleterious and problem elements (Cu, P, As, Pb, AMD etc.)

- Identify and quantify trace elements

- Economic viability of an ore

-

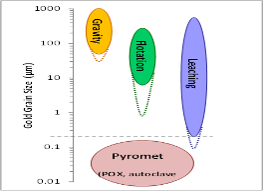

PROCESS SELECTION

The optimal extraction method for an ore is determined systematically using process selection. Deportment studies at AMTEL allows for a ground up approach to understanding how an ore may behave and whether the metals are in a form that may be recoverable. By providing a complete breakdown of the mineralogical distribution of an element in an ore, our clients gain comprehensive and accurate information on metallurgical performances.

Proper process selection will develop a process that also meets specific environmental and economic requirements. The final product will provide our clients with optimal recoveries and project economics, while minimizing risks.

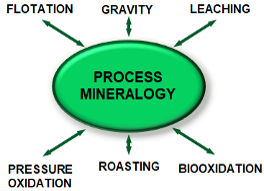

Process Optimization

For over 20 years AMTEL has been helping our clients optimize their operations. Plants are often faced with such challenges as low concentrate grades, poor performance, or lower than expected recoveries. Most issues can be fixed without significant capital costs by having changes to existing operations.

A full understanding of the process mineralogy of an ore will identify and quantify issues and potentials for improvement.

AMTEL specializes in:

- Tailing grade minimization and chemical stability

- Concentrate grade optimization

- Improving recovery strategies, including diversion

- Minimizing reagent consumption

Metallurgical Test-Work

AMTEL has a fully equipped metallurgical laboratory to backup and confirm any mineralogically identified improvements. Metallurgical test work performed in conjunction with mineralogical analysis allows for a comprehensive understanding of the process and serves as a guide for targeted test work.

Our state-of-the-art surface analytical techniques can be used to determine what surface effects are controlling floatation and leach behaviors.

Trace Element Analysis

AMTEL is a world leader in the mineralogical application of trace analysis techniques. A variety of techniques are used in the microbeam analysis of elements present in mineral grains at trace concentration levels.

Gold, PGE, and other precious metals can hide in the crystal lattices of otherwise invaluable minerals in minute amounts. With the modernization of mining and increased tonnages these minute amounts can add up to a substantial return. Hidden opportunities have been discovered by performing trace element analysis on minerals at AMTEL.

Analytical Techniques

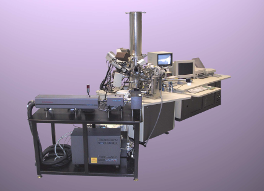

Surface Analysis

AMTEL is one of the pioneers in the use of static secondary ion and laser microbeam technology for the analysis of mineral surfaces. A wide range of equipment performing functions specialized to address specific process-related chemical issues has been established over the years.

By analyzing a surface one can obtain a good understanding of the underlying factors that control chemical process kinetics. Moreover, how the process kinetics can selectively be enhanced is naturally provided as well.

The speciation of surface chemicals can determine whether or why there may be adverse impacts to a process. AMTEL has routinely demonstrated the ability to speciate, image and quantify precious metals sorbed on individual mineral grains.

New potentials can be reached by better understanding surface dependent reactions and how to optimize them.

Analytical Techniques